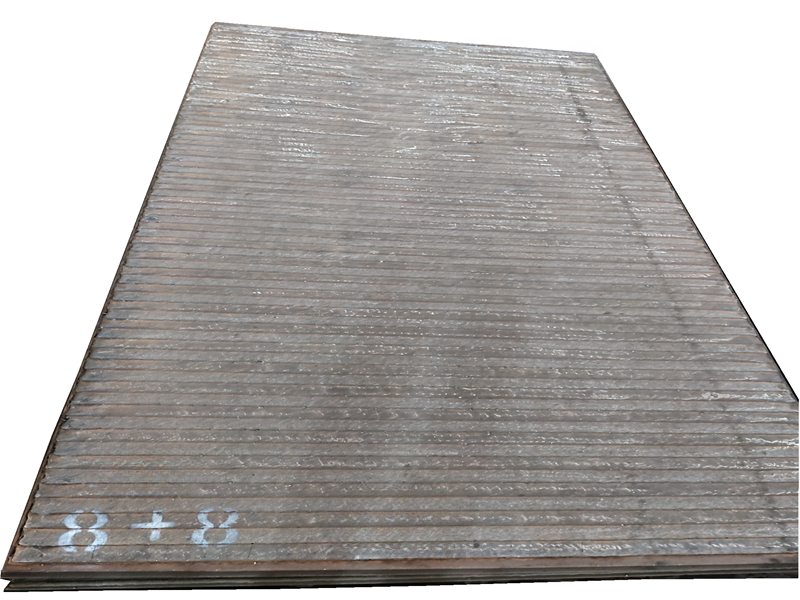

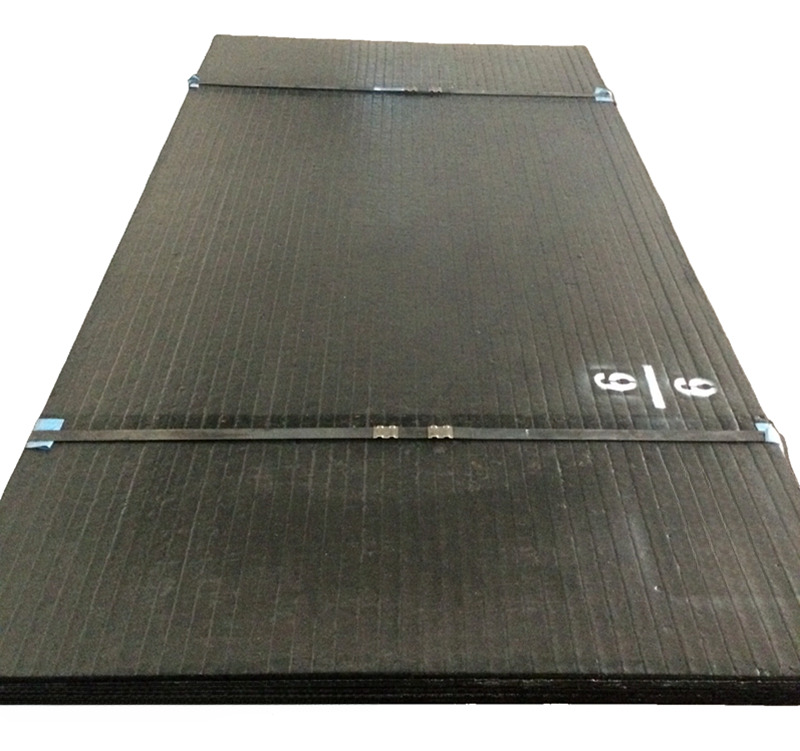

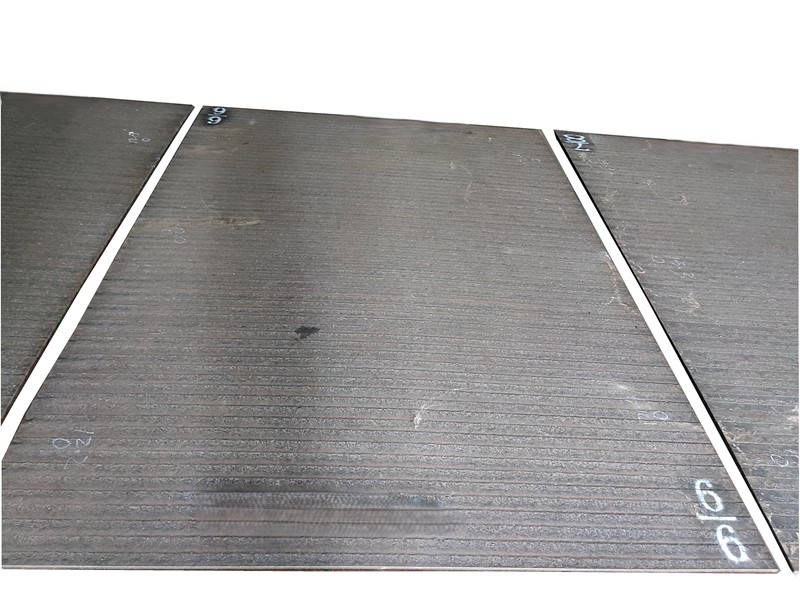

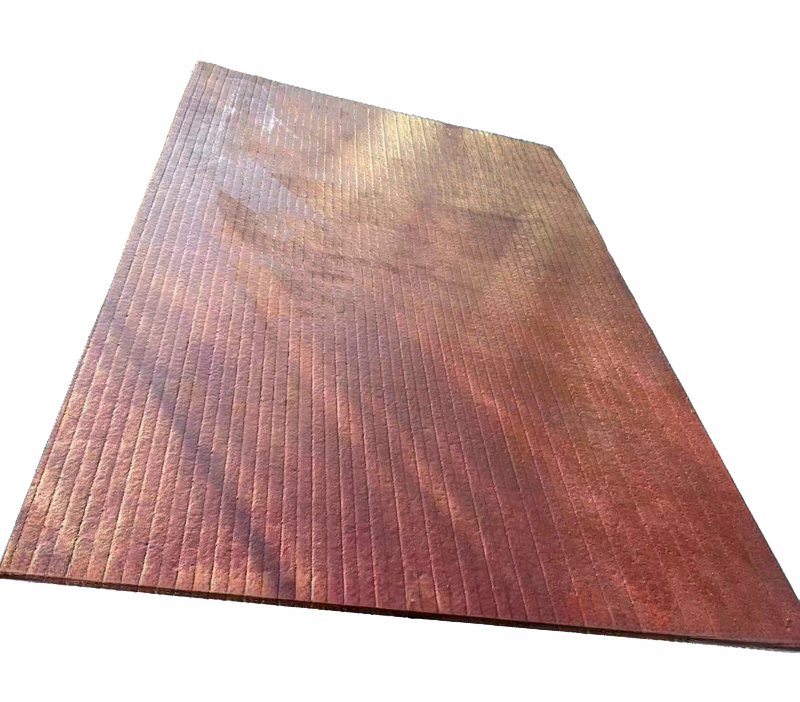

Chromium carbide overlay plate AT-P100 is composed of two parts: low carbon steel plate and alloy wear-resistant layer cladded through open arc welding.

The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness, which provides comprehensive performance of strength, toughness and plasticity to resist external force.

It is made by welding chromium carbide particles onto a steel base plate through a welding process. The high hardness self-protecting alloy wire or alloy powder is welded evenly on the substrate by special equipment and automatic welding process, and the number of composite layers is from one layer to two layers to multiple layers.

The alloy wear-resistant layer of the composite wear-resistant steel plate is completely metallurgically bonded to the substrate.

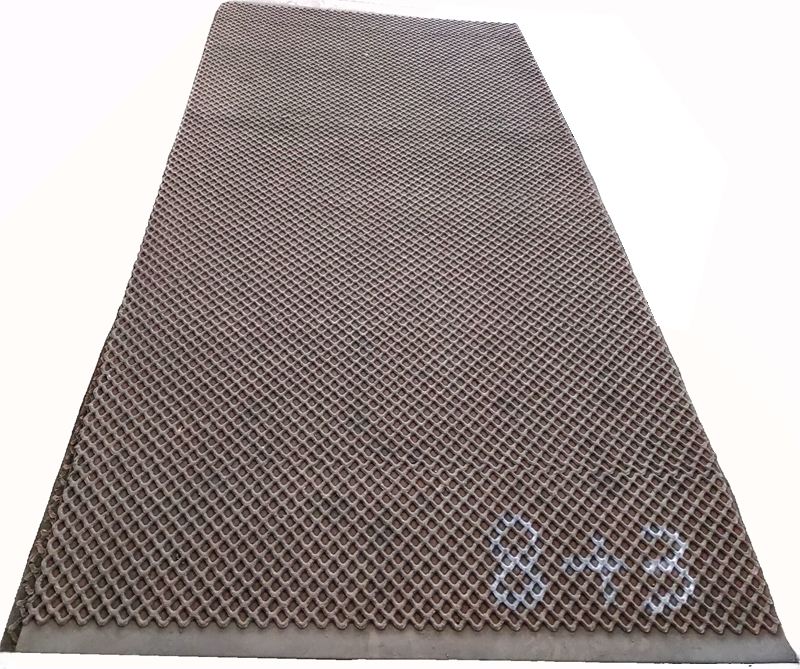

The chromium carbide create a hard surface that is highly resistant to wear & abrasion, making it ideal for use in industries such as mining, construction, and manufacturing.

CCO plate is commonly used in applications where equipment is subjected to high levels of wear and tear, such as conveyor belts, chutes, and crushers.

It offers a cost-effective solution for extending the lifespan of equipment and reducing maintenance costs.