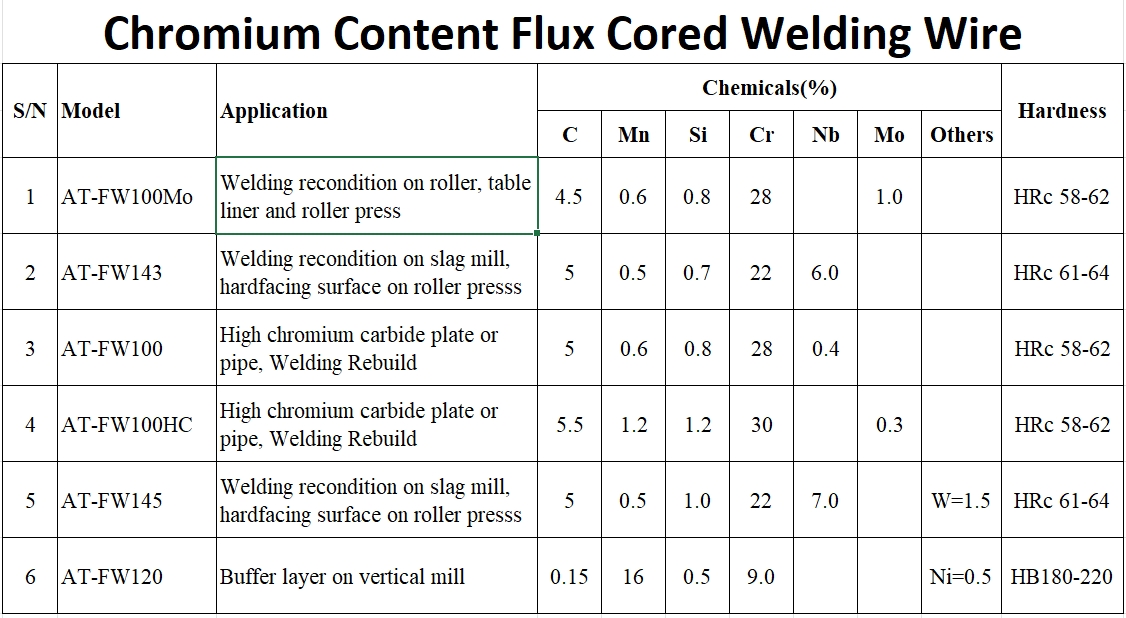

Abrasion-Tech chromium flux cored wire which enables a Cr-Mo-V alloyed deposit for semi automatic and automatic surfacing.

It is good for customer to repair and build up worn components and (or) provide cladding of components subject to all types of abrasion, impact, corrosion or temperature.

Our products protect high-wear components in plants and machinery, and provide a very economical and long-lasting solution to a wide range of wear problems.

With the application of weld overlays, most new or rebuilt components can meet service life targets not achievable under original OEM conditions, and our team can assist welding engineers in developing these processes.

The flux cored welding wire that we supply are available in a variety of packing options for small portable welding equipment to heavy industrial or automated welding applications.

Available in smaller size Ø1.2/Ø1.6mm in standard 15kg/reel and larger size Ø2.4/ Ø2.8/ Ø3.2mm on 25kg coils or 150/250kg each drum.