Welding hardfacing repair is a valuable technique for maintaining and restoring metal surfaces, offering numerous benefits for various industries.

It is an essential tool for preserving the integrity and functionality of equipment and machinery, ultimately contributing to the efficiency and success of businesses.

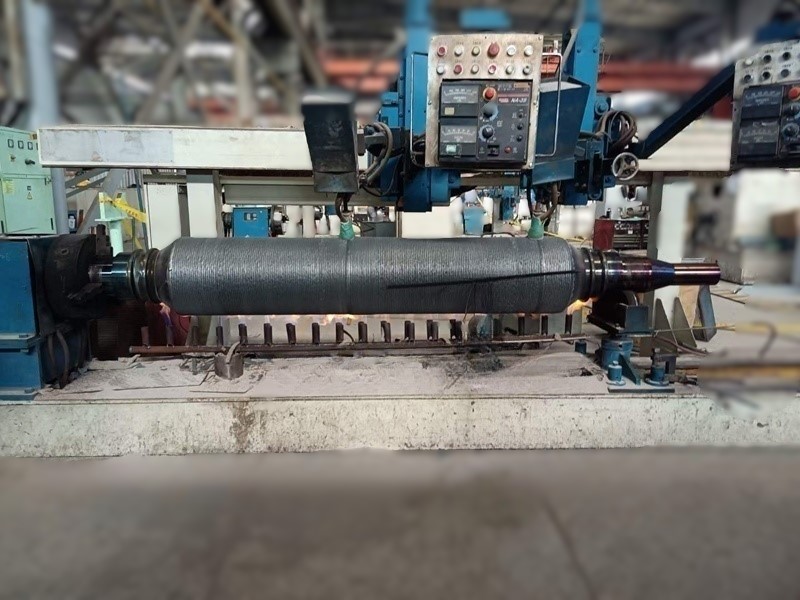

In a cement plant, the wear and tear on equipment such as rollers and table liners is a common issue that can lead to decreased efficiency and increased maintenance costs. To address this problem, it is important to implement effective wear solutions that can prolong the lifespan of these critical components.

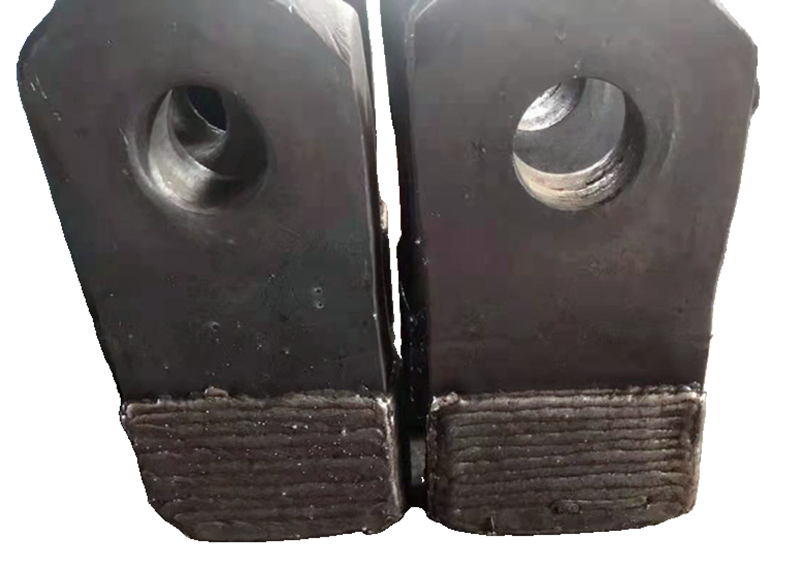

One popular wear solution for rollers and table liners in cement plants is the use of high quality wear-resistant materials-Chromium Carbide Hardfacing Overlay. These materials are specifically designed to withstand the abrasive nature of the cement manufacturing process, which involves the grinding of raw materials and the movement of heavy loads. By using wear-resistant materials, plant operators can reduce the rate of wear on rollers and table liners, leading to longer service life and lower maintenance costs.

Another effective wear solution for rollers and table liners is the application of protective coatings or liners. These coatings can provide an extra layer of protection against abrasion, corrosion, and impact, helping to extend the lifespan of the equipment. Additionally, some coatings can also improve the performance of rollers and table liners by reducing friction and enhancing material flow.