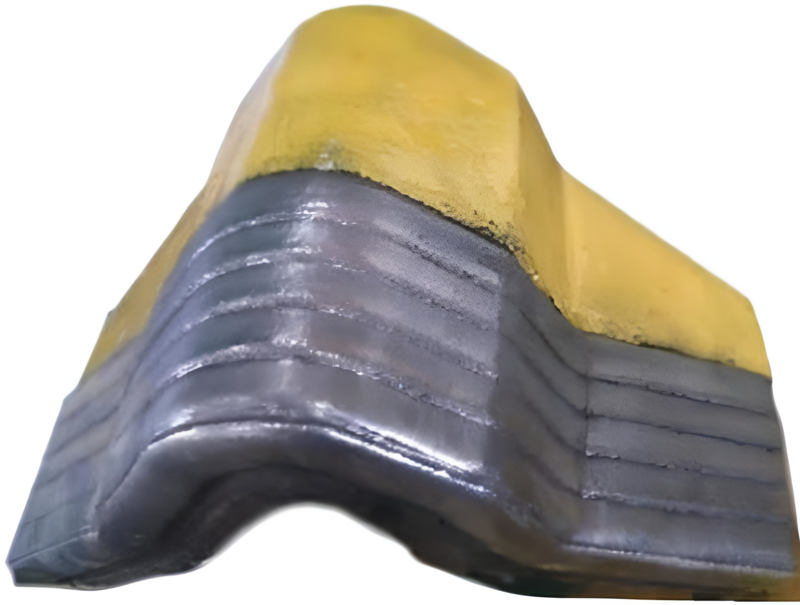

Plasma welding overlay has emerged as a highly effective solution for combating wear in a variety of industries. This advanced welding technique offers numerous advantages over traditional methods, making it an attractive option for companies looking to extend the lifespan of their equipment and reduce maintenance costs. You will get much benefits of plasma welding overlay as a wear solution and discuss its applications in different industries.

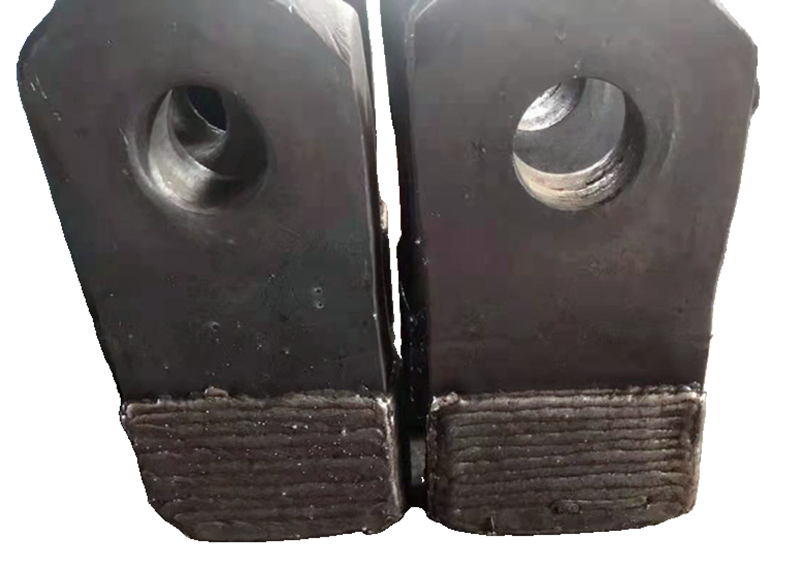

In the mining industry, plasma welding overlay is commonly used to protect equipment such as buckets, shovels, and crushers from abrasive wear caused by rocks and minerals. By applying a wear-resistant overlay to these components, companies can extend their lifespan and reduce the frequency of maintenance and replacement, resulting in cost savings and increased productivity.

In the oil and gas industry, plasma welding overlay is utilized to protect drilling equipment, pipelines, and valves from corrosion and erosion caused by harsh operating conditions. By applying a corrosion-resistant overlay to these components, companies can prevent costly downtime and environmental damage, ensuring the safe and efficient operation of their facilities.

Plasma welding overlay offers a cost-effective and efficient solution for combating wear in a wide range of industries. Its ability to produce high-quality overlays with minimal dilution and distortion, its versatility in terms of materials and applications, and its proven track record in enhancing wear resistance make it a valuable tool for companies looking to improve the lifespan and performance of their equipment. As technology continues to advance, plasma welding overlay will likely play an increasingly important role in the maintenance and optimization of industrial systems, helping companies stay competitive in a rapidly evolving marketplace.