Roller and table liners play a crucial role in the efficient operation of a cement plant. These components are essential for ensuring the smooth functioning of the grinding process, which is a key step in the production of cement.

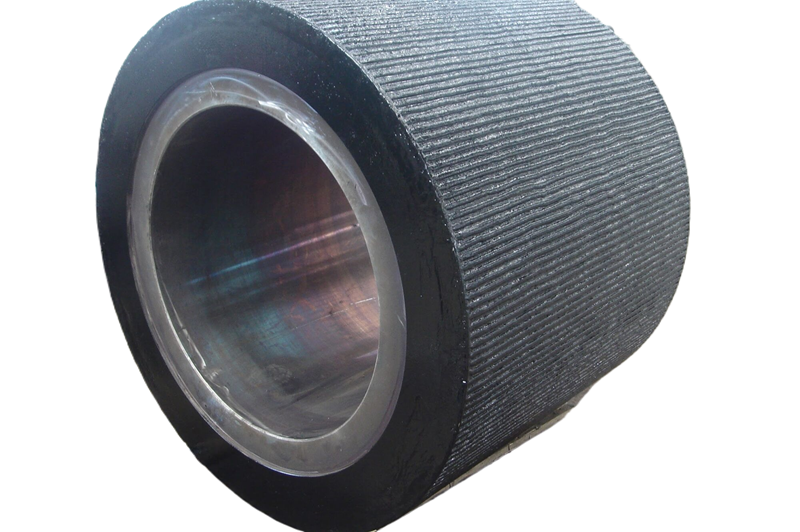

Roller and table liners are critical components in the grinding process of a cement plant. The roller is a key part of the vertical roller mill, which is used to grind raw materials into a fine powder. The table liner, on the other hand, is located underneath the rollers and helps to ensure a smooth grinding process. Together, these components work to crush and grind the raw materials, such as limestone and clay, into a fine powder that is then mixed with other materials to produce cement.

Roller and table liners in a cement plant is to protect the grinding machinery from wear and tear. The constant friction and pressure involved in the grinding process can cause significant damage to the rollers and table if they are not properly protected. Roller and table liners act as a barrier between the raw materials and the machinery, reducing the impact of the grinding process on the equipment and extending its lifespan.

Besides protecting the machinery, roller and table liners also play a crucial role in ensuring the quality of the final product. The smooth surface of the liners helps to maintain a consistent grinding process, resulting in a more uniform powder that is essential for producing high-quality cement. Any irregularities or damage to the liners can affect the grinding process and lead to inconsistencies in the final product, compromising its quality.

The following flux cored welding wires are recommended as wear solution to welding rebuild and recondition on wear resistant component.