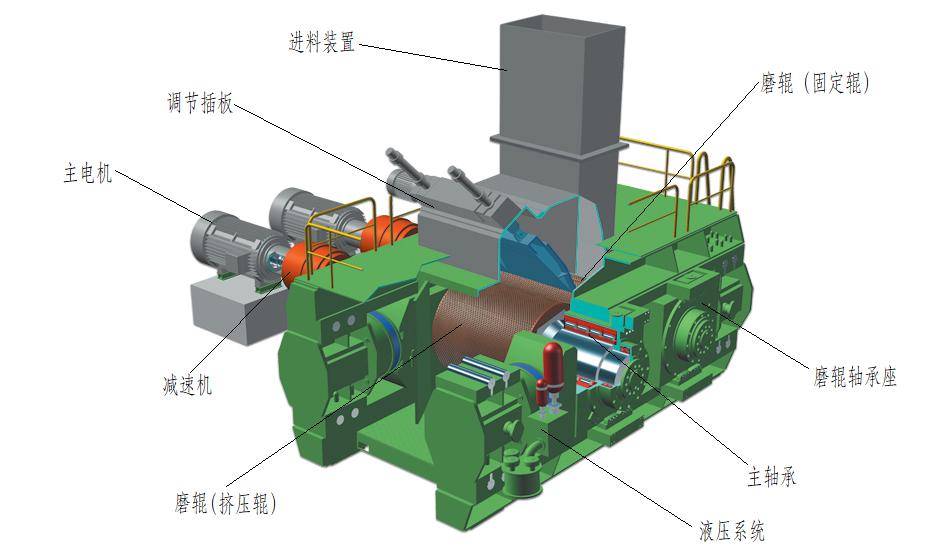

The roller press consists of two counter-rotating rollers that press the raw materials against a rotating grinding table. This high-pressure grinding process helps to reduce the energy consumption and increase the production capacity of cement plants. By utilizing the roller press, cement manufacturers can achieve a finer and more uniform grind, resulting in a superior quality product.

The key advantages of the roller press is its ability to operate at lower energy consumption levels compared to traditional grinding mills. This not only reduces the environmental impact of cement production but also helps to lower operating costs for manufacturers. Additionally, the roller press can be easily integrated into existing cement production lines, making it a versatile and adaptable solution for plant upgrades and expansions.

Furthermore, the roller press offers a more flexible and customizable approach to cement production. Manufacturers can adjust the pressure and speed of the rollers to optimize the grinding process for different types of raw materials, resulting in a more consistent and reliable product. This level of control allows cement plants to meet the specific requirements of their customers and adapt to changing market demands.

The roller press is a valuable asset for cement production that offers numerous benefits to manufacturers. Its high-pressure grinding technology helps to improve energy efficiency, increase production capacity, and enhance the quality of the final product. By investing in roller press technology, cement plants can stay competitive in the industry and continue to meet the growing demand for high-quality cement.

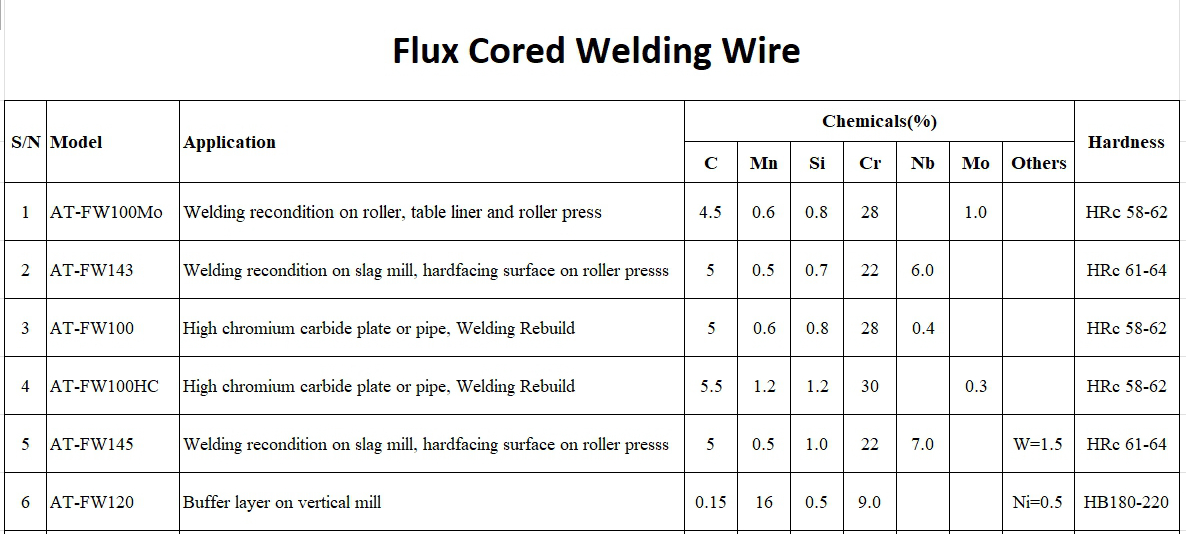

The following flux cored welding wires are recommended as wear solution to welding rebuild and recondition on wear resistant component.