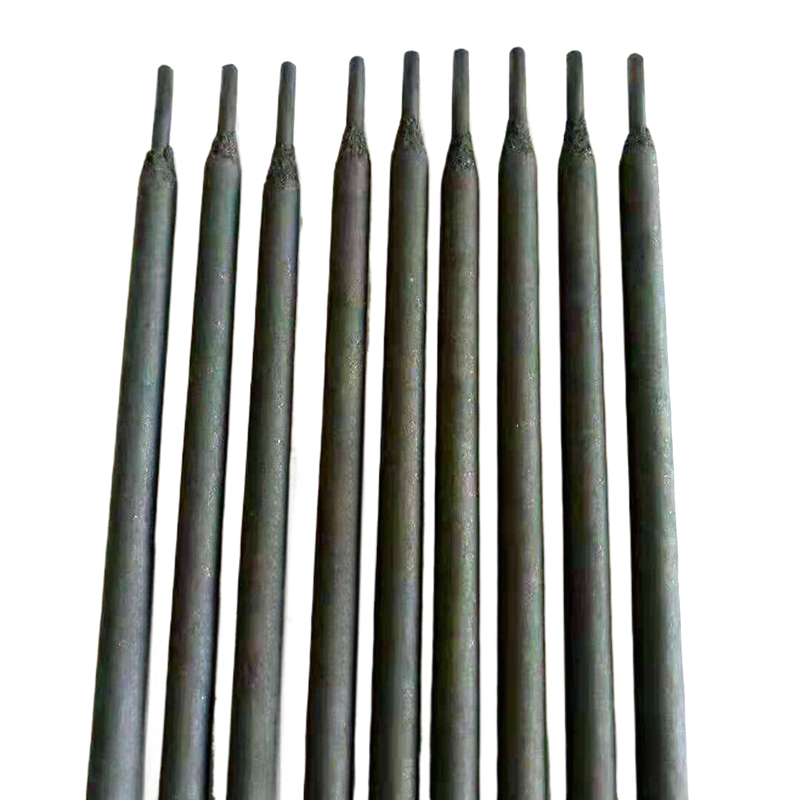

Welding Rods are classified by use

1. Structural Steel Electrode: including carbon steel electrodes and some low alloy steel electrodes

2. Chrome-Molybdenum Welding Electrode: the weld metal of this type of electrode has different degrees of high temperature resistance.

3. Tungsten Carbide Welding Electrode:The material is ideal for hardfacing overlay welding on wear-resistant parts in various industries such as steel mills, power plants, cement plants, etc…

4. Stainless Steel Electrode: The weld metal of this type of electrode has different degrees of anti-atmospheric or corrosion-resistant working ability at normal temperature, high temperature or low temperature.

5. AWS E6013 Carbon Steel Welding Electrode: The weld metal of this type of electrode has a certain low temperature resistance working ability.

6. Cast Tungsten Carbide Welding Rod: This type of electrode is used for welding or repairing cast iron.

7. Nickel Alloy Electrode: This type of electrode is used for welding of nickel and nickel alloys, as well as for welding and surfacing of dissimilar metals.

8. Copper Alloy Electrode: This type of electrode is used for the welding of copper and copper alloys, as well as for the welding and surfacing of dissimilar metals, and the welding repair of cast iron.

9. Aluminum Alloy Electrode: These electrodes are used for welding, repairing and surfacing of aluminum and aluminum alloys.

Welding Rods has different diameters and lengths, and the diameter of the electrode is generally selected according to the thickness of the component during use. Commonly used electrode diameters are as Φ1.6, Φ2.0, Φ2.5, Φ3.2, Φ4.0, Φ5.0