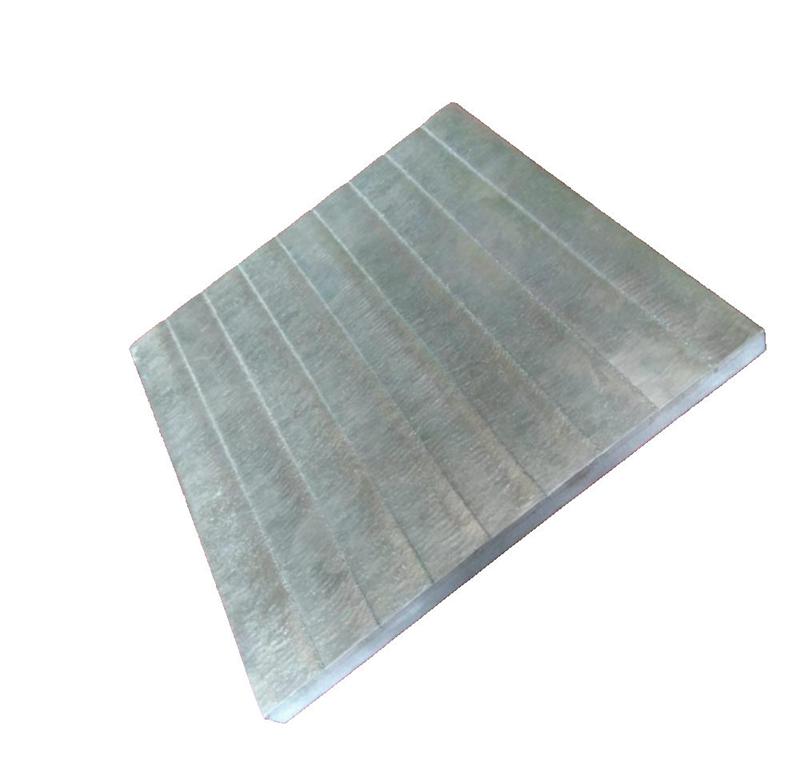

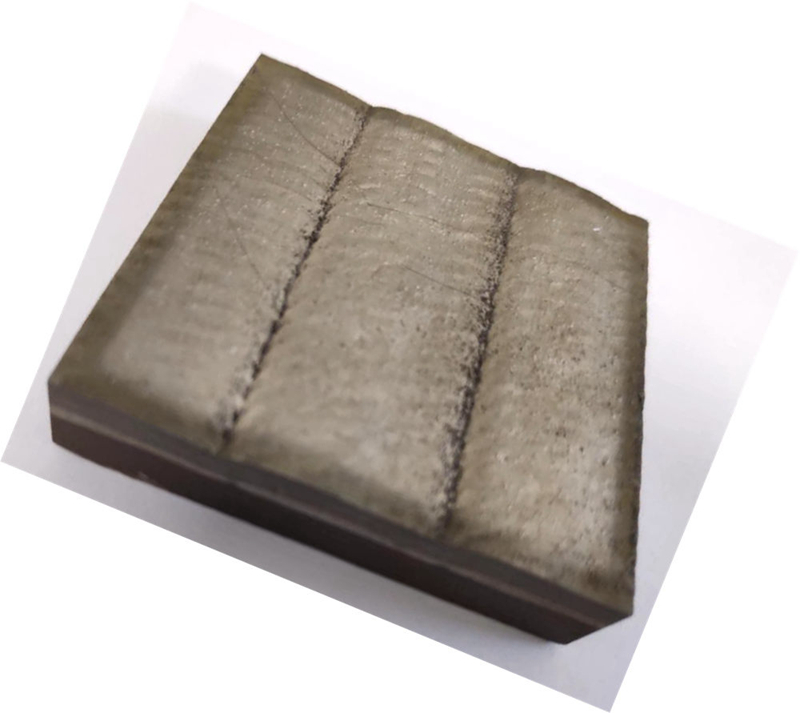

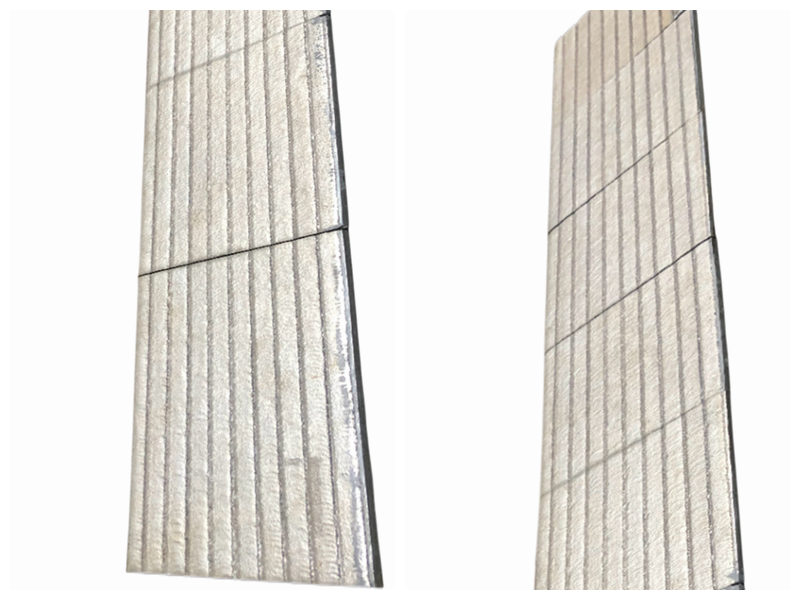

The overlay is achieved by welding a layer of tungsten carbide onto a steel plate.

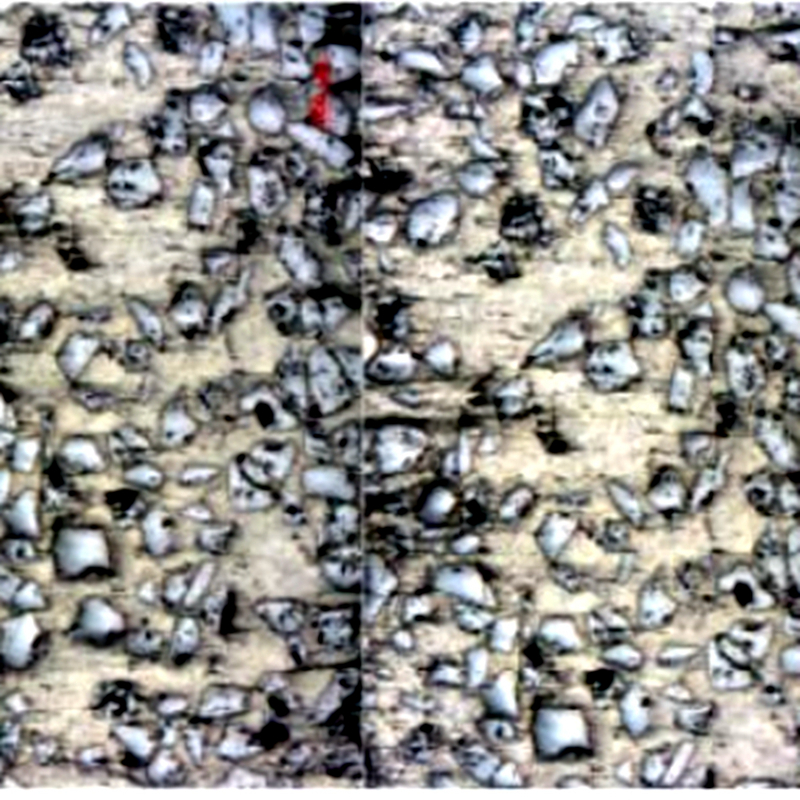

Tungsten carbide is a hard and dense material that is known for its exceptional wear resistance.

By overlaying it onto a steel plate, the resulting composite material exhibits improved resistance to abrasion, erosion & impact.

Tungsten carbide overlay steel plate is a type of composite material that combines the high strength and toughness of steel with the wear resistance of tungsten carbide. It is commonly used in industries such as mining, construction, and manufacturing, where equipment is subjected to severe wear and abrasion.

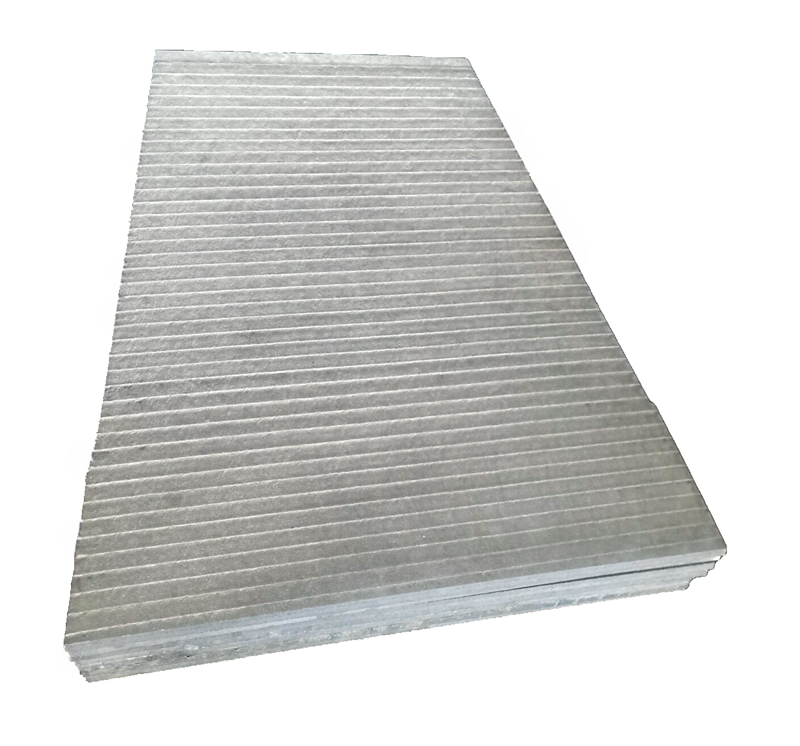

The tungsten carbide overlay steel plate is typically used to protect surfaces that are exposed to harsh conditions, such as chutes, hoppers, and conveyor systems. It helps to extend the service life of equipment and reduce maintenance costs.

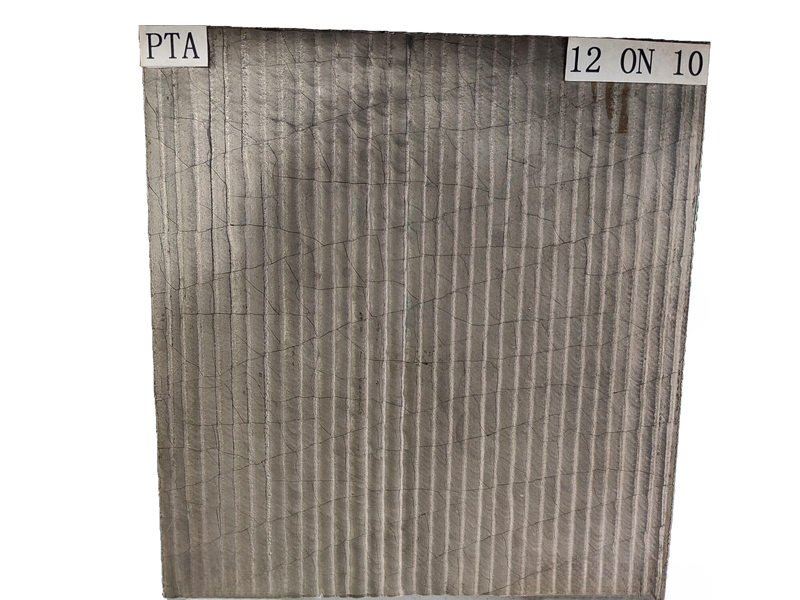

The thickness of the tungsten carbide overlay can vary depending on the application and requirements.

It is usually applied through a welding process, such as submerged arc welding or plasma transfer arc welding, to ensure a strong bond between the tungsten carbide and the steel plate. Overall, tungsten carbide overlay steel plate is a durable and cost-effective solution for protecting equipment from wear and extending its lifespan in demanding industrial environments.