Wear resistant steel pipes and elbows are made from high-quality steel alloys that are specifically formulated to provide exceptional hardness, toughness, and resistance to abrasion.

The composition of these alloys typically includes elements such as chromium, molybdenum, and nickel, which enhance the material's wear resistance properties.

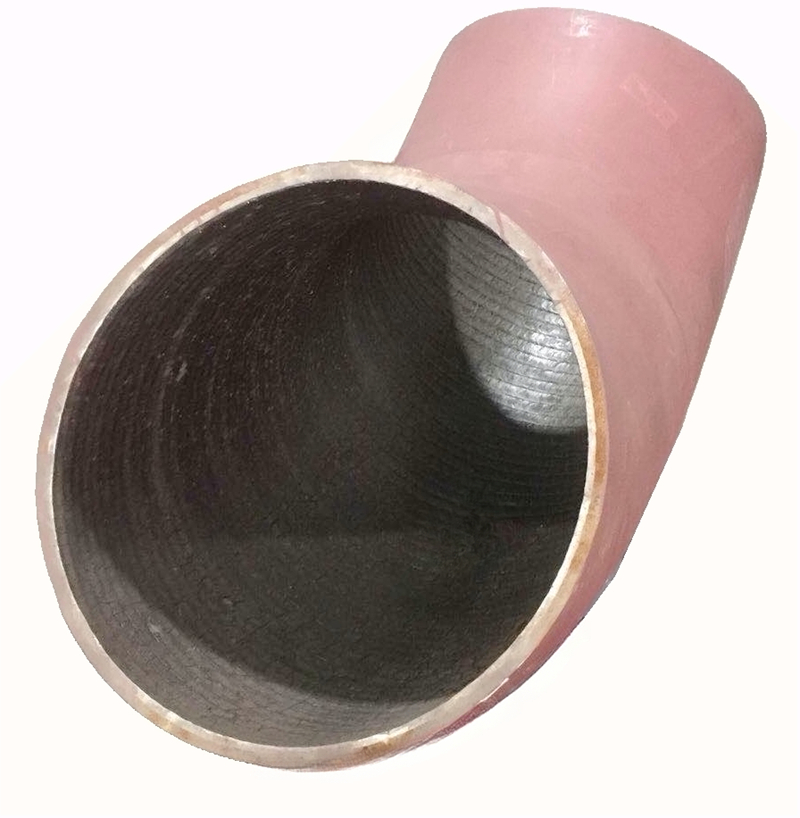

The inner surface of wear-resistant steel pipes and elbows is often lined with a layer of wear-resistant material, such as ceramic, chromium carbide, or tungsten carbide.

This lining provides an additional layer of protection against abrasion and erosion, extending the lifespan of the components.

Product Features:

Outlasts mild steel pipe by average of 5+ times

Reduces maintenance cost, & unplanned outages

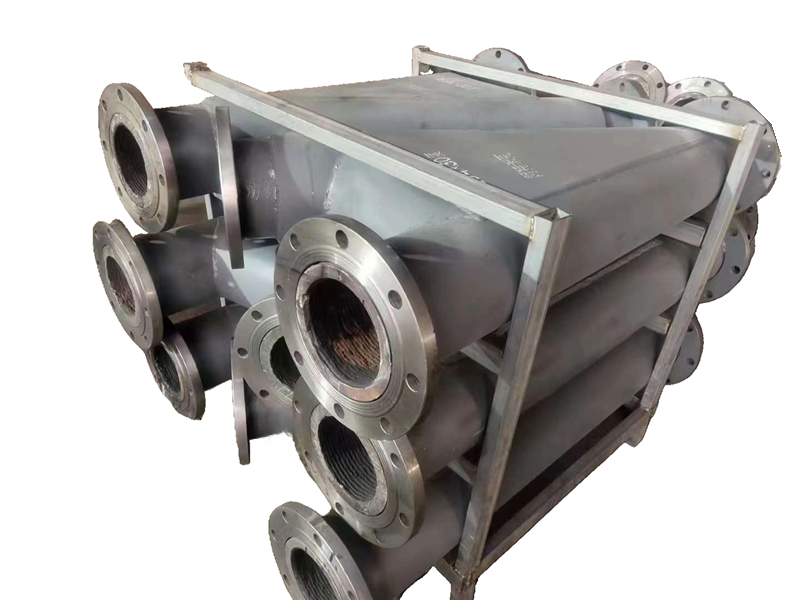

Wide range of diameters

Standard pipe sizes

Easy installation & field repair

Monolithic material with no laminations

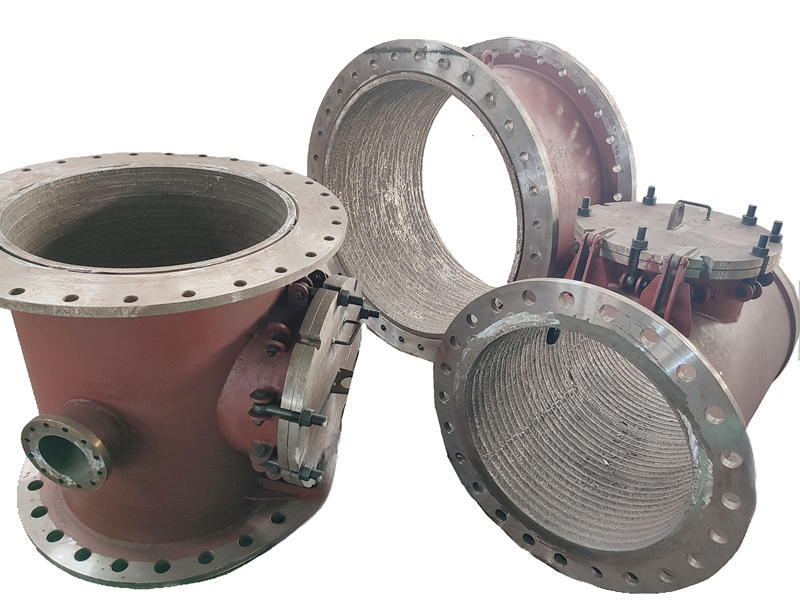

Available in straights, bends, wyes, tees & reducers

Abrasion resistant up to 450° F

Tremendous design & fabrication flexibility

Great replacement for heavy, unweldable castwear pipe

Wear-resistant steel pipes and elbows are specialized components used in industries where abrasive materials, high-velocity flows, and severe wear conditions are present.

These components are designed to withstand the erosive forces, impact, and wear caused by the flow of materials such as slurry, ore, sand, and other abrasive substances.

The beneafits of using wear-resistant steel pipes and elbows include:

Excellent wear resistance:

The materials can withstand the erosive forces, impact, and wear caused by abrasive materials, ensuring longer service life and reduced maintenance costs.

Resistance to corrosion:

Wear-resistant steel pipes & elbows are also resistant to corrosion, making them suitable for use in corrosive environments.

High flow efficiency:

The smooth inner surface of these components reduces friction and turbulence, allowing for efficient flow of materials.

Versatility:

Chromium carbide overlay wear-resistant steel pipes & elbows can be customized to fit various sizes and configurations,

making them suitable for a wide range of applications in industries such as mining, cement, power generation, and dredging.