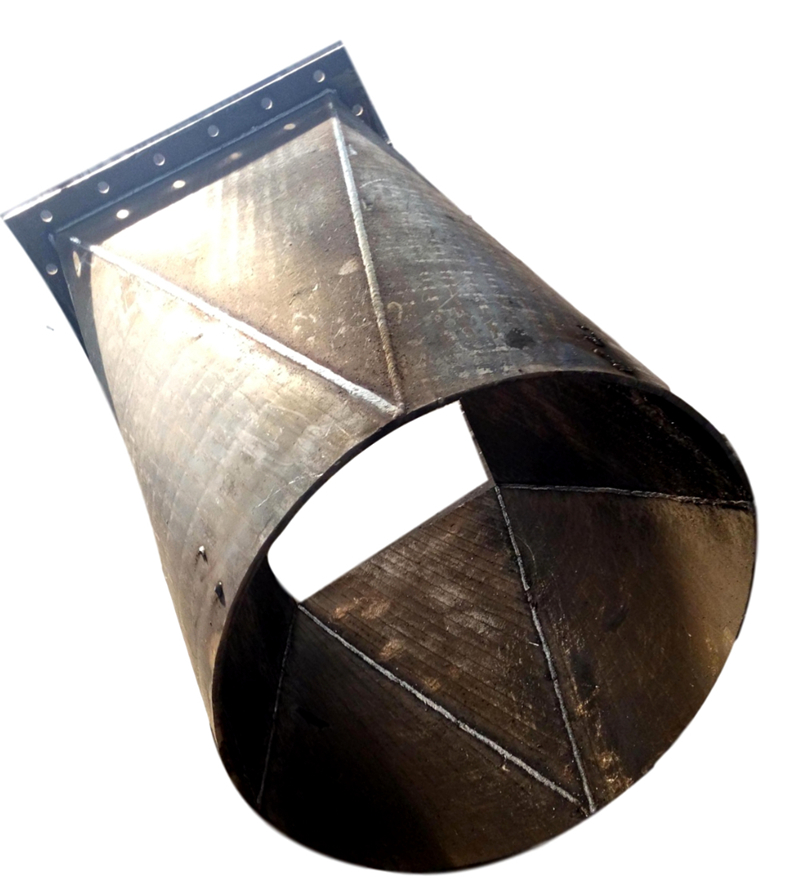

The process of fabricating chromium carbide overlay hardfacing liners involves several steps, starting with the selection of the base material. The base material is typically a high-strength steel that can withstand the harsh operating conditions that the liner will be subjected to. Once the base material is selected, it is cut to the desired shape and size using specialized cutting equipment.

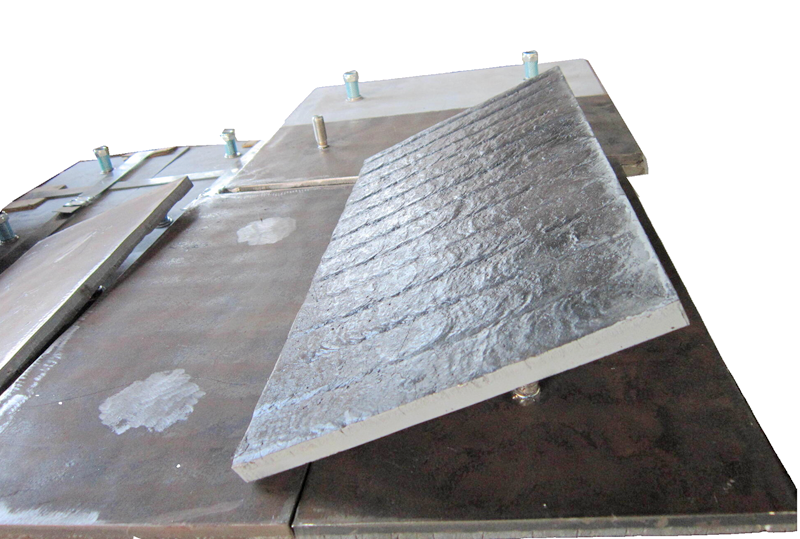

Next, a layer of chromium carbide overlay is applied to the base material using a welding process. Chromium carbide is a hard and wear-resistant material that is ideal for protecting against abrasion and impact. The overlay is applied in multiple layers to achieve the desired thickness and hardness. The welding process used to apply the overlay must be carefully controlled to ensure proper adhesion and uniform coverage.

After the chromium carbide overlay has been applied, the liner is heat-treated to improve its hardness and toughness. This process involves heating the liner to a specific temperature and then rapidly cooling it to achieve the desired properties. Heat treatment is essential for ensuring that the liner can withstand the extreme conditions it will be exposed to in service.

Once the liner has been fabricated, it is carefully inspected to ensure that it meets the required specifications and quality standards. This may involve non-destructive testing methods such as ultrasonic testing or dye penetrant inspection to check for any defects or imperfections. Any issues that are identified during inspection must be addressed before the liner can be installed.