Flanges and pipe fittings are essential components in the construction and maintenance of piping systems in various industries such as oil and gas, petrochemical, power generation, and water treatment. These components play a crucial role in ensuring the integrity and efficiency of piping systems by providing a secure and leak-proof connection between pipes, valves, and other equipment.

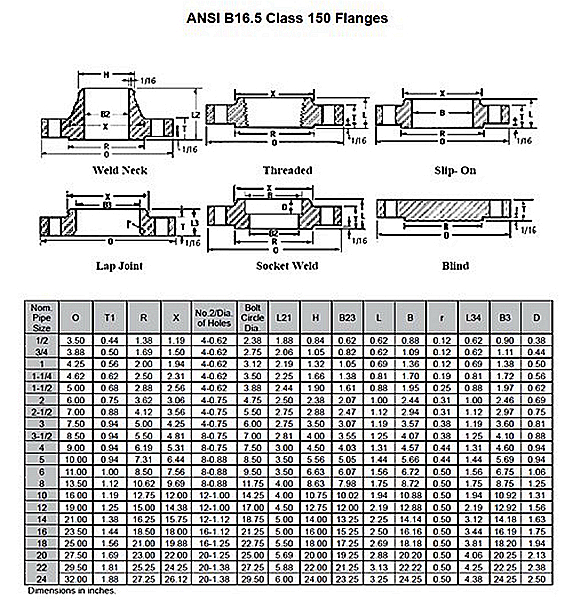

Flanges are flat, circular discs with evenly spaced bolt holes that are used to connect pipes, valves, and other equipment to form a piping system. They are available in various materials such as carbon steel, stainless steel, and alloy steel to suit different application requirements. Flanges are classified based on their facing, pressure-temperature ratings, and dimensions, and they come in different types such as weld neck, slip-on, blind, and socket weld flanges.

The selection of flanges and pipe fittings is critical to the performance and safety of a piping system. Factors such as the type of fluid, pressure, temperature, and environmental conditions must be considered when choosing these components. Proper installation and maintenance of flanges and pipe fittings are also essential to ensure the integrity and reliability of the piping system.

Flanges and pipe fittings are vital components in the construction and maintenance of piping systems in various industries. Their role in providing a secure and leak-proof connection between pipes, valves, and other equipment cannot be overstated. Therefore, it is crucial to select the right type of flanges and pipe fittings and ensure their proper installation and maintenance to guarantee the integrity and efficiency of the piping system.