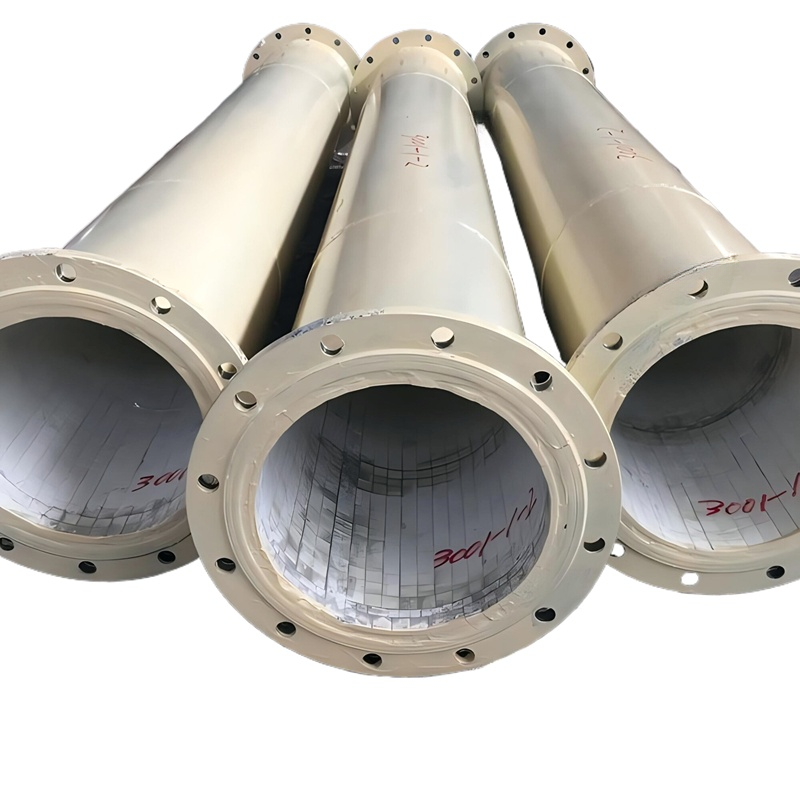

Ceramic lining pipes and elbows are made from high-quality alumina ceramic material. The key benefits of ceramic lining pipes and elbows is its superior abrasion resistance. The hard ceramic lining effectively protects the inner surface of the pipes and elbows from the abrasive materials flowing through them, significantly extending their service life and reducing maintenance costs. This abrasion resistance also helps to maintain the efficiency of the material transport system, as it minimizes the risk of blockages and reduces downtime.

Besides abrasion resistance, ceramic lining pipes & elbows also offer excellent corrosion resistance.The ceramic material is chemically inert and does not react with most chemicals and substances, making it ideal for use in corrosive environments.This corrosion resistance ensures that the pipes and elbows remain intact and free from damage, even when exposed to corrosive materials.

Furthermore, ceramic lining pipes and elbows are designed to provide a smooth inner surface, which helps to minimize friction and reduce pressure drop during material transport. This smooth surface also prevents material build-up and reduces the risk of clogging, ensuring a continuous and efficient flow of materials through the system.

The installation of ceramic lining pipes and elbows is a straightforward process that can be carried out by experienced professionals. The pipes and elbows are custom-designed to fit the specific requirements of each application, ensuring a precise and secure fit. Once installed, the ceramic lining provides reliable protection and performance, allowing the system to operate smoothly and efficiently for an extended period.

Ceramic lining pipes and elbows are essential components in industries that handle abrasive materials. Their superior abrasion and corrosion resistance, coupled with their smooth inner surface and easy installation, make them a cost-effective and reliable solution for material transport systems. By investing in ceramic lining pipes and elbows, industries can ensure the longevity and efficiency of their operations, ultimately leading to increased productivity and reduced maintenance costs.

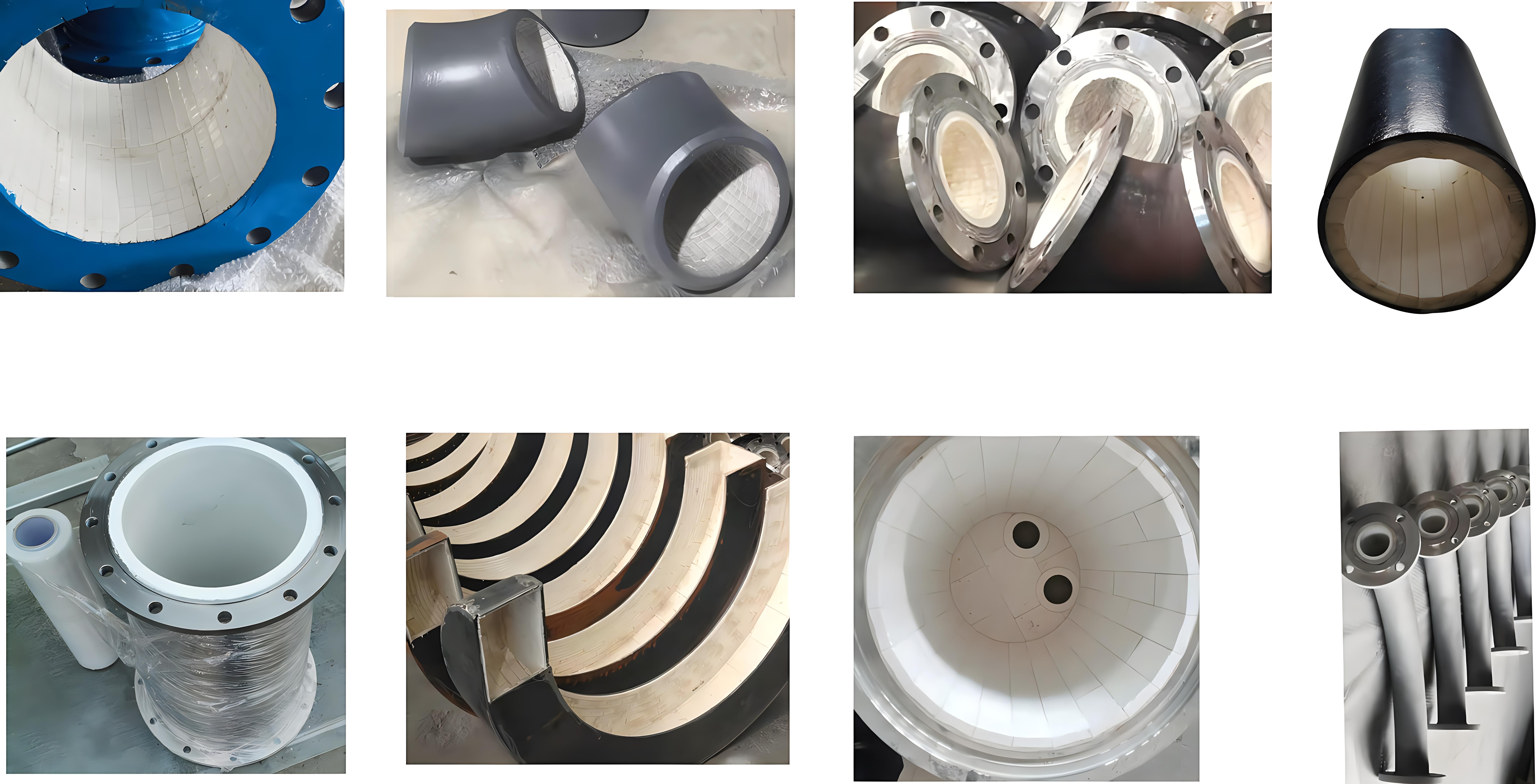

Manufacturing technique options

Option 1: Lined with ceramic tiles in size 150*33/28*13mm, 150*43*47*50mm, 100*35*32*13mm, etc.

Option 2: Lined with alumina ceramic tubes or elbow in diameter 100~300mm & length 100~500mm.

Option 3: Lined with ceramic tile in size 150*150mm,300*300mm,500*500mm etc.

Option 4: Lined with curved locking tiles made to order