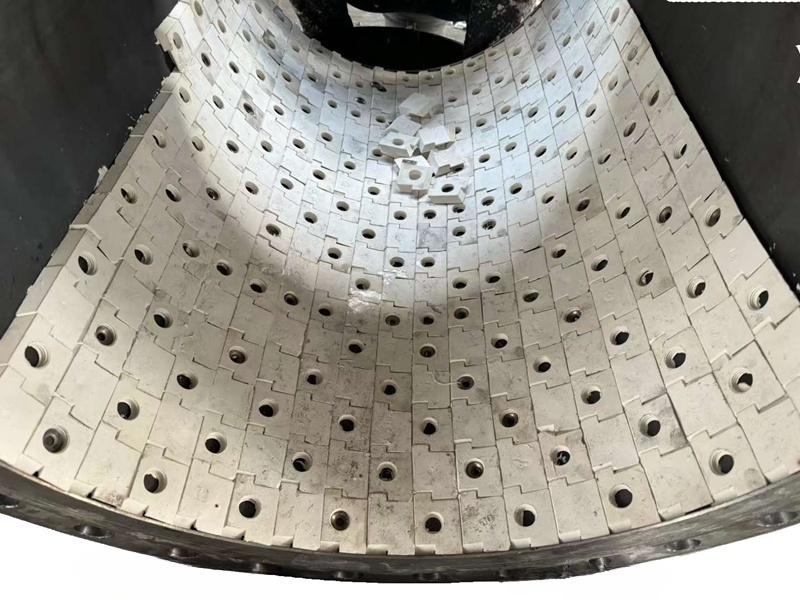

Wear-resistant ceramic lining plates are commonly used in industries such as mining, power generation, and chemical processing, where equipment is subjected to extreme conditions. We supply a full suite of ceramic materials and shapes which enables us to meet the requirements of our customers in providing products that will maximise wear protection.

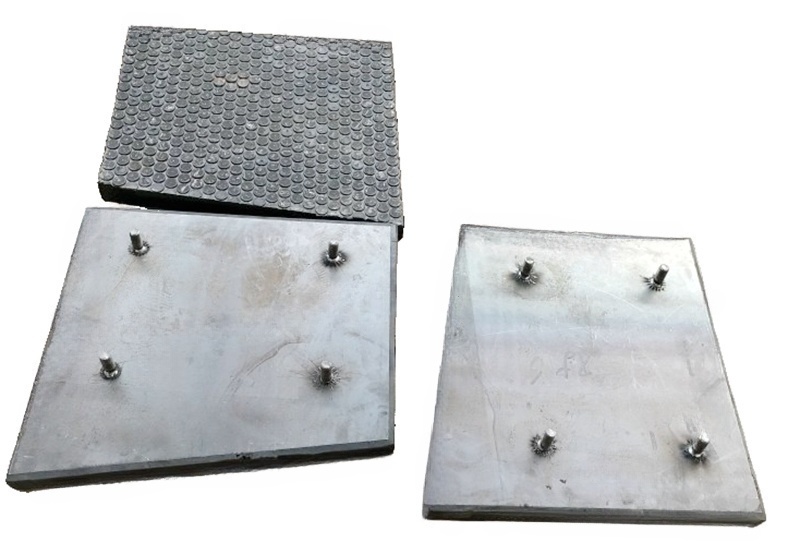

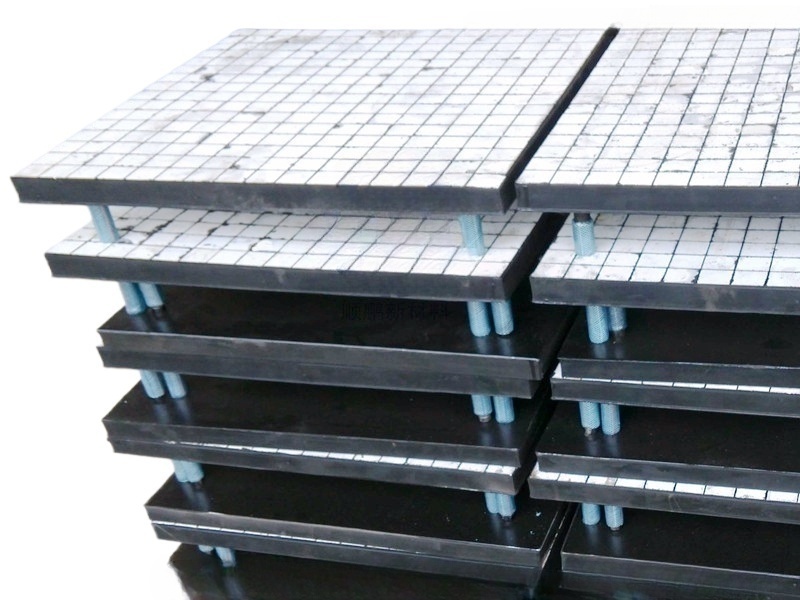

The materials also can be supplied as rubber and steel-backed or have direct bond ceramic allowing for quick and easy installation.

Typical Applications:

Chutes, Impact Plates

Reclaimers, Hoppers

Piping, Skirt Liners, Cyclones

Wear resistance:

Alumina corundum ceramics, the hardness reaches above HRA85, the wear resistance is 271.5 times that of steel;

Impact resistance:

The toughened ceramic formula ensures that the ceramic is not easily broken. The unique spherical design and high-quality buffer layer can resist the impact of large materials;

High temperature resistance:

Can operate at 0℃-250℃ for a long time;

Acid and alkali resistance:

The rubber adopts a new formula of acid and alkali resistance rubber, which can resist weak acids and weak alkali;

Anti-falling:

The ceramic rubber steel plate is vulcanized in one piece, and the combination is very strong; each piece of ceramic has penetrating bolts passing through the bottom steel plate, and is firmly welded, double insurance;

Easy installation & replacement:

It is provided with a whole lining board, which facilitates

Reduce maintenance:

Super wear resistance greatly reduces the frequency of maintenance, saving costs and labor.

In addition to their protective properties, ceramic liners also offer thermal insulation, which can help to improve energy efficiency and reduce heat loss in industrial processes.

This makes them a valuable asset in applications where temperature control is critical.