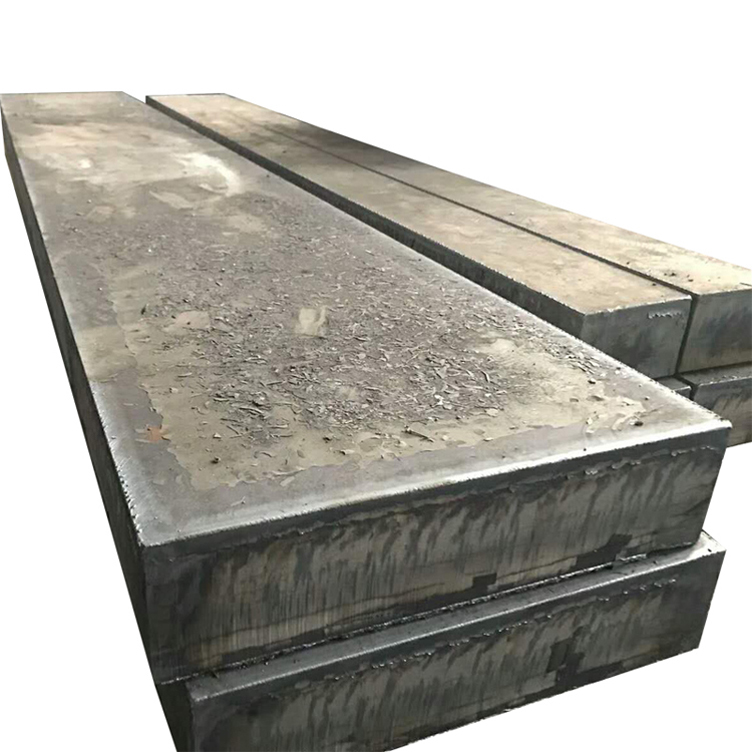

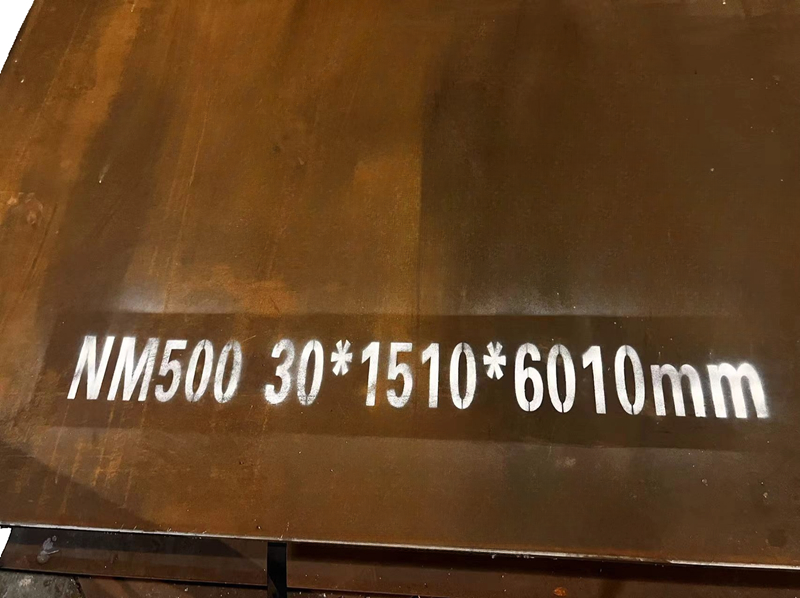

NM500 steel plate is available in a range of thicknesses, widths, and lengths, and can be customized to meet specific requirements.

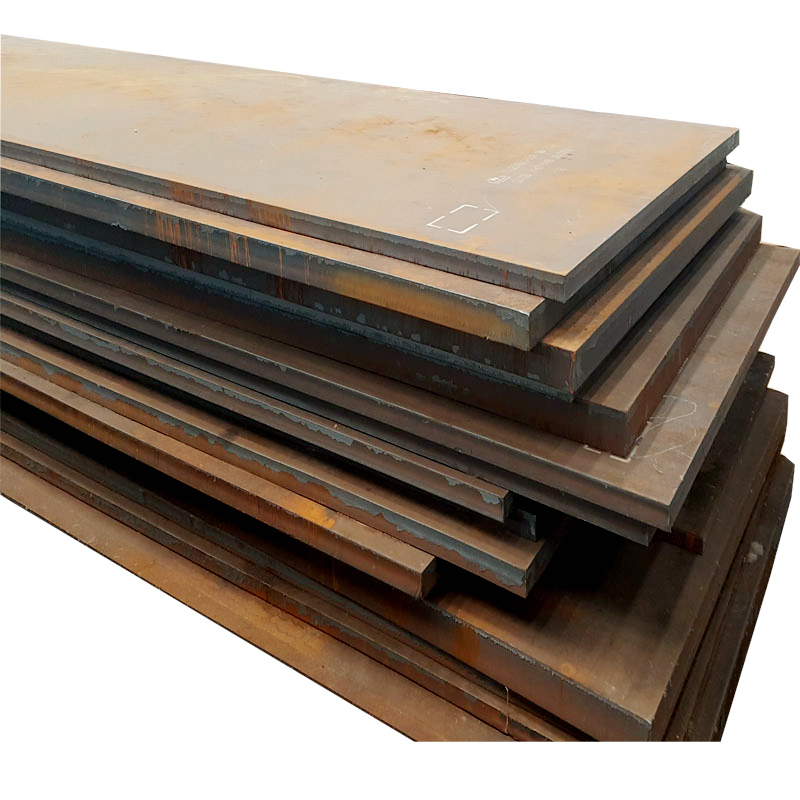

It is typically made from low-alloy or carbon steel, and may be coated with a protective layer to improve its corrosion resistance.

NM500 steel plate is commonly used in applications that require high strength, durability, and resistance to wear and tear, such as in construction, mining, and heavy equipment manufacturing. It is also used in the production of pressure vessels, boilers, and other industrial equipment that must withstand high temperatures and pressures.